|

|

|

|

SDC 0.5/V ~ 5W- 1.5WN-3WN

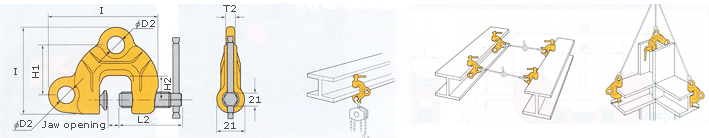

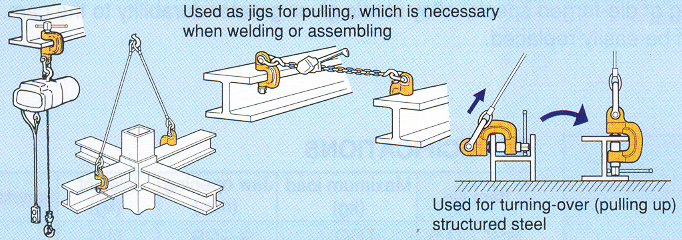

This screw clamp is for all-purpose use, such as raising and lowering, lateral (horizontal) pulling and turning-over lifting.

FEATURES

The lightweight and compact clamp can be used for a variety of operations such as lifting, hanging, turning over, and pulling of work pieces.

A positive clamping force is generated with the screw and the round cams (special spring-loaded) at no load and even when vibrations occur during operation.

The main body is made by die-forging of special alloy steels in one piece, which is optimally tempered for maximum strength and durability.

High-frequency quenching of special alloy steels gives greater durability to the cam.

The main body is a baked-on finish. |

Always lift work pieces at 2 or more points for safety. Always lift work pieces at 2 or more points for safety. |

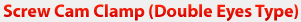

SPECIFICATIONS-DIMENSIONS TABLE

| Item No. |

Rated capacity (ton) |

Jaw opening (mm) |

L |

L2 |

H |

Hi |

H2 |

Di |

D2 |

Ti |

T2 |

Weight (kg) |

Remarks |

| SDC0.5N |

0.5 |

0~25 |

146 |

89 |

1 19 |

69 |

30 |

27 |

27 |

46 |

15 |

1.9 |

|

| SDC IN |

1 |

0~40 |

199 |

121 |

157 |

90 |

45 |

32 |

32 |

50 |

16 |

3.4 |

|

| SDC1.5WN |

1.5 |

10~50 |

214 |

121 |

164 |

96 |

45 |

36 |

32 |

50 |

18 |

6.0 |

|

| SDC2N |

2 |

0~40 |

215 |

121 |

169 |

96 |

45 |

36 |

32 |

55 |

19 |

4.5 |

|

| SDC3N |

3 |

0~40 |

237 |

136 |

181 |

103 |

50 |

45 |

35 |

60 |

20 |

5.9 |

|

| SDC3WN |

3 |

35~75 |

270 |

136 |

191 |

1 13 |

50 |

45 |

35 |

60 |

20 |

7.8 |

|

| SDC5N |

5 |

0~50 |

270 |

146 |

215 |

123 |

55 |

50 |

37 |

80 |

43 |

11.0 |

|

|

|

| Screw Cam Clamp (J-type) |

| |

|

|

|

SJC 0.5 ~ 3

This is the ideal clamp for the temporary suspension of a chain block or an electric hoist from a steel beam.

FEATURES

The lightweight and compact clamp can be used for a variety of operations such as lifting, hanging, turning over, and pulling of work pieces.

A positive clamping force is generated with the screw and the round cams (special spring-loaded) at no load and even when vibrations occur during operation.

The main body is made by die-forging of special alloy steels in one piece, which is optimally tempered for maximum strength and durability.

High-frequency quenching of special alloy steels gives greater durability to the cam.

The main body is a baked-on finish. |

EXAMPLES OF USE

Always lift work pieces at 2 or more points for safety. Always lift work pieces at 2 or more points for safety. |

|

|

DIMENSIONS TABLE

| Item No. |

Rated capacity (ton) |

Jaw opening (mm) |

L |

Li |

H |

Hi |

H2 |

Di |

Ti |

T2 |

Weight (kg) |

Remarks |

| SJC 0.5 |

0.5 |

0~25 |

148 |

89 |

103 |

45 |

35 |

22 |

40 |

14 |

1.6 |

|

| SJC1 |

1 |

0~40 |

182 |

109 |

1 15 |

45 |

42 |

26 |

46 |

16 |

2.6 |

|

| SJC2 |

2 |

0~40 |

195 |

121 |

137 |

45 |

57 |

36 |

55 |

25 |

3.8 |

|

| SJC3 |

3 |

0-40 |

220 |

136 |

155 |

50 |

65 |

45 |

60 |

30 |

4.8 |

|

|