|

|

|

Notice: Any and all claims arising from the use of ELTECH Blocks products are subject to the strict performance of all inspection and maintenance instructions outlined herein. All instruction apply to all products, as application.

ELTECH Blocks Distributors are instructed to furnish this information to customers and users of ELTECH Blocks products.

This sheet is available on request free of charge in any quantity.

Safety Caution Plate and Nameplate should never be painted over or removed. If rendered illegible, or missing, contact factory for new plate (s).

A copy of this instruction is shipped with every ELTECH Blocks product or invoice line item.

BASIC POLICY ON REPAIR OF WORM OR DAMAGED ITEMS:

If any reason an item does not worn, and repair is desired, do not attempt to disassemble or repair. Return item prepaid to our Sewree Plant for inspection and estimate of repair cost. (Contact us in advance to discuss specifics, or to obtain factory authorization for field repair, if desired.) If, in user's opinion, conditions require reworking of item without returning to factory, or without obtaining factory authorization, such rework or repair will be undertaken entirely at user's risk and cost

| LUBRIACTION SCHEDULE: |

LUBRICATION FREQUENCY UNDER CONDITIONS OF: |

Swivels & swivel balls

Bronze bushed blocks & sheaves

Roller bearing blocks & sheaves |

Continuous

operation

24 hours

8 hours

24 hours |

Intermittent

operation

14 days

14 days

14 days |

|

Type Lubricant: Either sodium or lithium base greases may be employed. Soda soap base greases are more fibrous and cohesive. Lithium soap base greases are excellent especially where excessive moisture is present.

|

REGULAR AND FREQUENT INSPECTION of all wire rope accessories is a must for safety. For Eltech Blocks products, all points listed below should be carefully observed, plus any other indicated by good field practice. Continuous surveillance and alertness is required under working conditions.

PERMANENT DEFORMATION (STRETCHING)on any part is a clear indication of overload. Part should be taken out of service immediately and replaced.

SWIVEL END PLAY (OR GAP) of more than 1/6" along the axis of a swivel is a danger signal. Remove from use immediately.

CHECK BLOCKS TO SEE IF SIDE PLATES ARE SPREADING.

This is a sure sign of overload. Remove from service for repair.

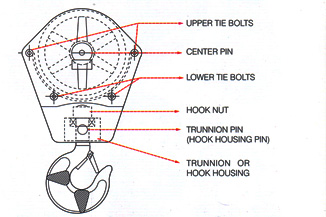

ANY LOOSENESS IN PLATES on blocks with tie bolts or stress pins is a sign of possible loose retaining them. Remove check weight (if any) and follow instruction in section on "anti-loosening provisions"

SHEAVE ALIGNMENT CHECK: Uneven groove or flange wear is evidence of sheave misalignment. Check for wobbly or loose sheaves this means bearing wear

SHEAVE GROOVE WEAR: Check for striations or corrugations in sheave groove, caused by rope wire. These can be costly on your rope life. If serious, sheave should be remachined or replaced.

ANY DISTORTION OR CRACK ON A HOOK OR FITTING is a signal that replacement is needed immediately.

HOOK NUT CALLING can occur in during disassembly foreign matter has gotten into threads. A galled nut cannot be forced. Return product prepaid to our plant, or contact us for instructions below.

CHECK ALL NUTS FREQUENTLY for any signs of backing off due to vibration or other causes. If necessary, re-tighten any loosened nuts, following instruction below.

If center pin retaining nut, see that section of this instruction.

If upper tie bolt nut, re-tighten firmly and re-stake throughly.

If lower tie bolt or stress pin nut, re-tighten nut firmly and

(a) re-stake if originally staked.

(b) If held by set-screw, re-tighten set-screw to re-establish jamming action against threads.

If lower trunnion pin nut, re-tighten nut firmly to point at which trunnion will just rotate, then re-tighten set-screw in nut as in above

Set screw where used on side nuts of blocks (center pin nuts, hook trunnion pin nuts, stress pin nuts etc.) are jammed radially into threads. Check set-screw for tightness, re-tighten firmly if needed to re-establish jamming action against threads.

This sheet is available on request free of charge in any quantity.

Safety Caution Plate and Nameplate should never be painted over or removed. If rendered illegible, or missing, contact factory for new plate(s).

A copy of this instruction is shipped with every ELTECH Blocks product or invoice line item.

TYPICAL BLOCK SHOWING VARIOUS POINTS OF RETAINMENT

Note:

Note: If center pin nut appears or is loose, or has backed off, follow tightening instructions in section on center pin re taining nuts. Then, re-tighten set-screw in nut as above.

Staking of all block side nuts not having set screws (tie bolt nuts, small stress pin nuts, hook trunnion nuts, center pin nuts, etc.) must be checked to see if still in original orientation. If nut has backed off, re-tighten and re-stake thoroughly, following instructions on center pin retaining nuts if this type. If in doubt about integrity of re-staking, tack weld nut as follows:

(a) if center pin nut, weld nuts, on both ends to side plate.

(b) if trunnion pin or stress nut weld nut to pin.

Cotter pins where furnished must remain in place, replace any damaged or missing cotter pin before resuming work.

Set screws on swivel barrels are staked in place at factory.

Check for any signs of backing out. If any re- tighten and re-stake thoroughly.

If in doubt, replace swivel & return to factory for check.

Check weight cap screws should always be tightened down, and locked either with (a) self -locking jam nut inside of side plate, or (b) lock-washer under head of cap screw (inside cheek weight counter-sink)

CENTER PIN RETAINING NUTS over-tightening may cause sheave bearing damage. Do nat alter factory setting without factory authorization. If emergency conditions require reworking of block without authorization from factory, the procedures below may be of assistance but will be undertaken entirely at user's risk and cost.

Consult block nameplate to determing sheave bearing type: B or BB bronze bushing T tapered roller bearing

If tapered roller bearing, tighten center pin retaining nut(s)until side play is eliminated from all sheave, nut(s) are tightened firmly.

Follow instruction on anti-loosening provisions of nuts and set-screws. |

|

|

|

|

|

|